The classification of KPK cranes and their mechanisms according to the standards STN ISO 4301 and FEM (Federation Europeenne de la Manutention) specifies the group into which the crane and its mechanisms are classified.

It serves:

- for commercial and technical negotiations between buyer and crane manufacturer for determination of required crane performance

- as a bases for the designer to prepare the analyses of crane and its mechanisms.

Selecting the right crane classification, or duty cycle, for an crane is critical for a customer who is trying to balance the initial investment of a crane system with the cost of future maintenance that will be required.

These four factors are the most important requirements that you should identify to make sure that your crane is specified for the correct duty cycle and classification:

- Rated load – Estimation of the loads lifted at or near capacity

- Service – Total hours in operation per day

- Number of lifts – Average lifts and trolley and bridge movements made each hour

- Distance – Average length of each movement

Other factors that may not directly affect the crane classification, but should still be taken into consideration when designing and specifying an crane, are:

- Speed – how quickly can the crane transfer materials or equipment ? How many lifts per hour can the crane perform ?

- Maintenance requirements

- Operating environment

- Future needs

Why Do You Need to Classify Cranes by Duty Cycle or Service Class ?

Crane service classifications allow you to select and build an crane that is the most economical and safest design for your lifting application.

The KPK specialists are always ready to provide help by classifying the crane according to the above standards.

Class of load spectrum Q1 až Q4

Q1 – Structures exceptionally lifting the nominal load and usually very weak loads

Q2 – Structures lifting only seldom the nominal load and usually loads of about 1/3 of the nominal load

Q3 – Structures lifting frequently enough the nominal load and usually loads between 1/3 and 2/3 of the nominal load

Q4 – Structures regularly loaded close to the nominal load

Group classification of the crane as a whole (classes A1 to A8) according to ISO 4301/1

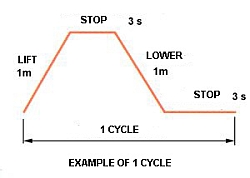

For the calculation of the classification, it is assumed that the working cycle of the crane starts from the time when the crane is ready to lift the load until the time when it is ready to lift the next load.

| Group classification of the crane as a whole (classes A1 to A8) according to ISO 4301/1 | |||||||||||

| Q4 | Q3 | Q2 | Q1 | Class of load spectrum according to ISO | Number of lifting cycles | Classes of use | |||||

| A2 to A4 | A1 to A3 | A1 to A2 | A1 | U0 to U2 | 63 000 | Non-regular occasional use, followed by long rest periods | |||||

| A5 | A4 | A3 | A2 | U3 | 125 000 | Non-regular occasional use, followed by long rest periods | |||||

| A6 | A5 | A4 | A3 | U4 | 250 000 | Regular in light service | |||||

| A7 | A6 | A5 | A4 | U5 | 500 000 | Regular use in intermittent service | |||||

| A8 | A7 | A6 | A5 | U6 | 1 000 000 | Irregular use in intensive service | |||||

| A8 | A8 | A7 to A8 | A6 to A8 | U7 to U9 | 4 000 000 | Use in severe intensive service | |||||

The following table shows several examples of classification for cranes and their mechanisms depending on crane application.

| Group classification | ||

| Application | of hoisting mechanism according to FEM 9.511 (STN ISO 4301) | of crane as a complete unit according to STN ISO 4301 (STN 270103) |

| Maintenance and assembly cranes for occasional use | 1Bm (M3) |

A3 till A4 (J1 till J2) |

| Assembly cranes for regular use | 1Am (M4) |

A3 till A5 (J2 till J3) |

| Workshop use | 1Bm till 1Am (M3 to M4) | A3 till A5 (J2 till J3) |

| Warehouse cranes | 2m till 3m (M5 to M6) | A4 till A6 (J2 till J3) |

| Magnet cranes | 3m till 4m (M6 to M7) | A6 till A8 (J3 till J6) |

| Automatic and special cranes | 4m till 5m (M7 to M8) | A6 till A8 (J3 till J6) |

By selection of hoist type (hoisting mechanism) it is important besides the specification of hoist carrying capacity according to the maximum weight of transporting load also the correct classification of hoisting mechanism.

Classification of mechanism e.g. lift, travel, etc.

The total period of use of the mechanism is a theoretical period that serves for the design of the parts of the mechanism, e.g. bearings, gears, shafts, etc.

The operating time Tm is considered only as the time when the mechanism is loaded !

The state of the loading mechanism L1 až L4 according ISO (1 to 4 by FEM):

L1 (1 by FEM) Mechanism or elements of mechanism subjected exceptionally to the maximum frequency of use and usually to very weak frequencies of use

L2 (2 by FEM) Mechanism or elements of mechanism subjected rather often to the maximum frequency of use and usually to weak frequencies of use

L3 (3 by FEM) Mechanism or elements of mechanism frequently subjected to the maximum frequency of use and usually to average frequencies of use

L4 (4 by FEM) Mechanism or elements of mechanism subjected regularly to the frequencies of use close to the maximum frequency of use

table 2 – The state of the loading mechanism according ISO and FEM

| The state of the loading mechanism according ISO and FEM | |||||||||||

| L4 | L3 | L2 | L1 | 1 | 2 | 3 | 4 | ||||

| M3 | M2 | M1 | … | T1 | under 15 min | 400 h | V 0,12 | … | 1Dm | 1Cm | 1Bm |

| M4 | M3 | M2 | M1 | T2 | from 15 min to 30 min | 800 h | V 0,25 | 1Dm | 1Cm | 1Bm | 1Am |

| M5 | M4 | M3 | M2 | T3 | from 30 min to 1 h | 1600 h | V 0,5 | 1Cm | 1Bm | 1Am | 2m |

| M6 | M5 | M4 | M3 | T4 | from 1 h to 2 h | 3200 h | V 1 | 1Bm | 1Am | 2m | 3m |

| M7 | M6 | M5 | M4 | T5 | from 2 h to 4 h | 6300 h | V 2 | 1Am | 2m | 3m | 4m |

| M8 | M7 | M6 | M5 | T6 | from 4 h to 8 h | 12500 h | V 3 | 2m | 3m | 4m | 5m |

| … | M8 | M7 | M6 | T7 | from 8 h to 16 h | 25000 h | V 4 | 3m | 4m | 5m | … |

| … | … | M8 | M7 | T8 | above 16 h | 50000 h | V 5 | 4m | 5m | … | … |

| Classification as per ISO norm | Mechanism utilization class | Average time of supposed daily operation – Tm | Total duration of use | Classification as per FEM norm | |||||||

Tab.3 – Relation between the classification according to FEM , ISO and GOST.

| ISO 4301-1 |

M1 | M2 | M3 | M4 | M5 | M6 | M7 | M8 |

| FEM 9.511 |

1Dm | 1Cm | 1Bm | 1Am | 2m | 3m | 4m | 5m |

| GOST | 1M | 2M | 3M | 4M | 5M | |||

| % ED | 25 | 30 | 40 | 50 | 60 | |||

| c/h | 90 | 120 | 150 | 180 | 240 | 300 | 360 | 360 |

|

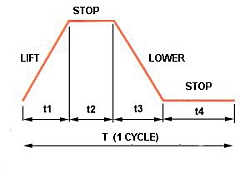

Intermittent Rating (%ED), Max.Number of Starts Per Hour Intermittent Rating (%ED), Max.Number of Starts Per Hour

%ED = [ (t1 + t3) / (t1 + t2 + t3 + t4 ) ] * 100 |

Average daily operating time Tm

Depends on operation time per day.It is calculated according to the following formula:

| Tm = ( 2 * H * C * T ) / ( 60 * V ) | [ hour / day ] |

![Average hook path H [m]](/wp-content/uploads/2018/09/vysang.gif) |

H – Average hook path [ m ]

C – number of cycles per hour [ – ]

T – working hours per day [ hour ]

V – hoisting speed [ m/min ]

Mechanism load spectrum

Example of classification calculation

1.1 Input data

- maximum weight of transported load Q = 5 000 kg

- average hook path H = 4 m

- number of cycles per hour C = 20

- required lifting speed V = 8 m/min

- working hours lifting mechanism T = 8 hours per day

- medium mechanism group

1.2 Calculation

Average daily operating time Tm:

Tm = ( 2 * H * C * T ) / ( 60 * V ) = ( 2 * 4 * 20 * 8 ) / (60 * 8) = 2,66 hours

According to Table 2 for medium operation is the lifting mechanism classification FEM – 2m (ISO -M5)

1.3 Choice of hoist

For lifting the load it is necessary to chose the hoist with carrying capacity 5000 kg, lifting speed 8 m/min and with classification according FEM 2m.