Modern metallurgy material storage.

The requirements on modern metallurgy material store

- direct and quick access to each assortment item - the highest possible usage of the stock space, especially the height and minimizing of needed operating spaces.

- improving the quality of sorting and recording the semi-product (blank) quality

- minimizing of needed labour and number of operating personnel

- complete and transparent records with all quantity, quality and economic data

- The old way of storing material at the customer (opaque with sophisticated handling volumes in the collection)

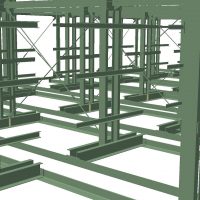

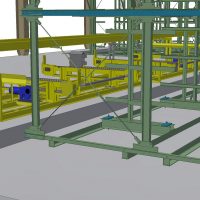

- Storing the material in storage systems KPK

- Rack columns are not anchored

- Alternative to storing material in cartridges

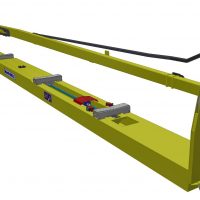

- The manipulátor

- Removing material from the rack

- Shelf occupancy check sensors

- Manipulator inserted into stacker

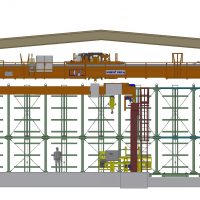

- Handling crane in front of storage

- Weighing truck

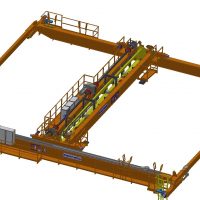

- The overhead crane with rotating trolley

- Transport trolley

- The shelf for steel sheets

- The platform for transporting material without persons

- Transport trolley 3000 kg

- The container 400 kg

- The platform for transporting material without persons

Example of storage systems

Storage system - variant No.3

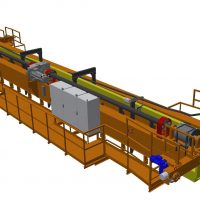

- The chain conveyor

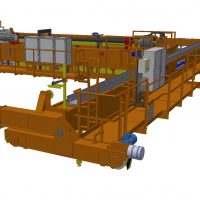

- The stacker

- Detail of stacker

- The stacker – general view

- The detail of columns

- The manipulator

- Input – output point of storage

- General view

- Overhead bridge cranes

- Detail of chain conveyor

- Detail of chain conveyor with stacker

Storage system with cartridges

- Control screen

- The overhead crane with rotating trolley

- Weighing truck

Storage system - variant No.2

- The cassette

- Storage cassettes on the shelf

- Storage cassettes on the shelf

- Stacker at the entry point

- The storage system shelves

- General view of the warehouse

Storage system - variant No.1

- The stacker over racks

- The control screen

- Stacker cranes

- The entry to the warehouse

Examples of various storage systems realizations

- The chain conveyor at the entrance in front of the shelves

- Storing the material in storage systems KPK

- Material on conveyor

- The manipulátor

- Removing material from the rack

- Manipulator inserted into stacker

- View of the stacker above the shelves

- Rack columns are not anchored

- Warehouse control computer

- Shelf occupancy check sensors

- Handling crane in front of storage

- Chain conveyor

- The cab of crane

- Handling crane in front of warehouse – view of warehouse

- View of the warehouse