KPK spol. s r.o.

The company KPK spol. s r.o. was established in the 1993. From the very beginning, it was involved in production and deliveries of hoisting equipment, cranes and storage systems.

Crane engineering

Crane engineering is realised according STN 270140, STN 332550 and comply with requirements of Notice MPSVR No.508/2009 Z.z. always taking into account the customer requirements (not standard dimensions and parameters, special locations and equipment, different types of controls, power supply and regulation....)

Calculations

Calculations of steel crane structures and runways are made according to EUROCODE 3, STN 270103 and relating standards, as an option also according valid standards DIN (DIN 15018,DIN 15019,....).

Examples of steel structures

- Lift Bridge

- Footbridge over the River Hron

- The silo

- The silo

- Transport truck for curved track

- Conveyor

- Detail of a retractable roof at a football stadium

- General view of the retractable stadium roof

- Detail of wheel bearing retractable roof

International exhibition

- International exhibition Nitra

- International exhibition

- International exhibition

- International exhibition

The certificates

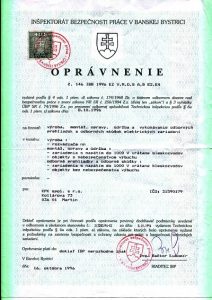

- Authorization 1

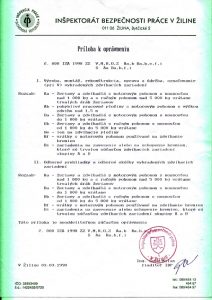

- Authorization 2

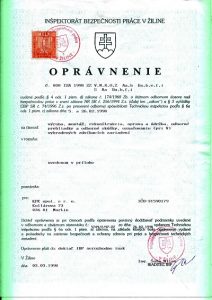

- Authorization 3

Assembly

Assembly (runway) under conditions stipulated in the Notice MPSVR No.508/2009 Z.z. paragraph 5,6 is performed at the manufacturer facilities with the aim to check the dimensions, functions and completeness of delivery. Then the crane is transported according to transport conditions in assembled state (or dismantled). Prior to assembly by the user the measurement document for crane runway according to STN EN 1090-2 with results of special inspection and check of electric equipment and earthing must be submitted. The longitudinal power supply equipment is usually a part of crane delivery and assembly. Usually the scope of crane delivery starts from the crane main switch inclusively. This use to be located near the crane runway. The power supply cable to the main switch is provided by customer.

The crane runways are delivered as individual girders, which are fitted on the hall column brackets or the complete crane runway together with columns is delivered. Integral part of the crane runway can also be the inspection platforms (inspection foot-bridges), traversing foor-bridges, climbing ladders (or staircases), connecting and anchoring parts.

The crane runways are delivered, manufactured and assembled, if not agreed otherwise, NO CHANGES OF RUNWAY'S GEOMETRY ARE ASSUMED.

Testing

Testing of cranes is performed according to Notice MPSVR No.508/2009 Z.z. paragraph 9 in an extend stipulated by STN 270142.

Checked are: lateral and vertical clearances, marking and inscriptions, technical parameters, performed is the static load test (with a load weight cca 125 % of crane carrying capacity) and dynamic load test (with a load weight 110 % of crane carrying capacity). The testing load for this checks IS PROVIDED BY CRANE USER. The tests can also involve the bridge (or arm) deflection measurements. The realised assembly of crane electric equipment and of longitudinal power supply must be documented by initial report from special inspection and special tests passed with satisfactory results.

The crane can be operated only after the official test for VTZz (special equipment), group A, has been passed or after the inspection (check) for VTZz group B according to Notice MPSVR No.508/2009 Z.z. paragraph11 and 12, Annex 6 has been performed.

Surface treatment

The cranes and crane runways are delivered with priming and top coat. Prior to coating the steel structure is usually sand blasted. The standard colour shades are:

- crane yellow

RAL 1033

RAL 1033 - hoist blue

RAL 5005 (or. green)

RAL 5005 (or. green) - drives blue

RAL 5005

RAL 5005 - craneway blue

RAL 5005

RAL 5005 - columns RAL 5005 (up to the height of 2100 mm from the ground - with safety strips

)

)

The black-yellow strips  according STN 018012 are applied on the crane dangerous areas. As option the crane and crane runway can be delivered also in other colours.

according STN 018012 are applied on the crane dangerous areas. As option the crane and crane runway can be delivered also in other colours.

Operation

The user can use the crane only under conditions stipulated in Notice MPSVR No.508/2009 Z.z.. in paragraph 8. According to STN 270143 the crane can be operated i.e. independently controlled only by qualified persons, who can prove to be familiarised with the regulation requirements for the operation of the technical equipment and trained respectively.

The qualification for operation is checked and registered by the revision technician. The crane remote control can be used only by authorised persons who have been trained for this operation.

For fixing and hanging of loads only slinging equipment according STN 270144, STN 270145, ISO 8792 (STN 270144), STN 270150 can be used.

During the crane operation it is necessary to perform the special inspections and tests according to Notice MPSVR No.508/2009 Z.z.. paragraph 12, annex 6 and 7

The crane runway must be, during its whole service life, permanently checked and maintained. The maintenance of crane runway is specified in STN EN 1090-2.

The schedule of special inspections and tests complies with requirements of Notice MPSVR No.508/2009 Z.z.. paragraph 3, annex 6 and 7.

FOR EXPORT DELIVERIES THE SAFETY TECHNICAL REQUIREMENTS OF THE CUSTOMER ARE RESPECTED.

|

Designation of KPK Cranes and Hoists

a/ type of crane M - overhead travelling crane P - portal gantry crane f the 2nd letter in the designation is Z, the letter P means - travelling PZM-overhead travelling hoisting equipment PZP- portal gantry travelling hoisting equipment S - column K - bracket b/ type of hoisting equipment Ž - crane ŽT - traverse crane Z - hoisting equipment ZT - traverse hoisting equipment ŽP - roof hanging crane c/ crane bridge beam number J - single girder D - double girder Note: for the column and bracket cranes the number of beams is not specified d/ type of crane bridge Z - welded, box-type design K - bracket crane trolley G - crane from the unit-built KPK KB system Note: if not specified the bridge or the arm is made of rolled profile e/ type of crane drive E - electrical R - manual Note: with column and bracket cranes the letter O means, that it is a slewing crane f/ crane carrying capacity in thousand kg for example: 3.2 is the carrying capacity of 3200 kg g/ crane span or radius in m The number presents the crane span for overhead travelling cranes or the arm radius for column or bracket cranes in m Designation example for two-beam overhead travelling crane, welded with electrical drive, with carrying capacity of 5 000 kg and with the bridge span 10 m. MŽDZE 5/10 | |||||||||||||||||